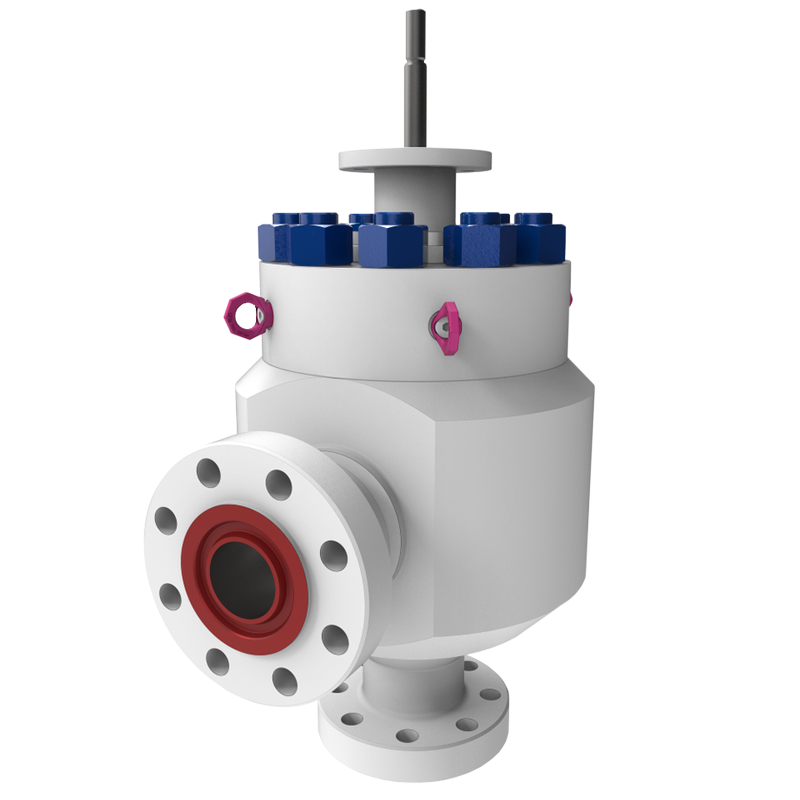

Adjustable angle choke valve

DTP

based on API 6A or B16.34 and customer requirements

NPS 1.13/16 - 9 (DN 46- 228)

NPS 2-12 (DN 50-300)

RF, RTJ as per B16.5 &B16.47

Hub connection

6B, 6BX as per API6A

Forged angle one-piece

Metal-seated with inserts in fully tungsten Carbide

Lip seals configuration

Blowout stem design

High capacity and accurate control also with minimum opening

Low noise and no vibration with multistage trim

Quick change of all internal parts with no bolting

Plug and trim material with excellent erosion resistance property available

Disks clamped without any internal threads

Ease maintenance without removal of actuator and instrument connections

Plug type: Balance (to minimize the actuator thrust) or Unbalance or Pressurized

Over or Under the plug flow configuration

One-piece tungsten sinterized trim for high erosion service

Manual: Gear with handwheel

Actuated: Linear Pneumatic/ Hydraulic, Electric or Stepper

Compliance with API 6A /B16.34 inspection and testing

Fire safe and fire tested as per API 6FA/607

Fugitive Emission as per ISO15848

PED 2014/68/UE

Available as per API 6A Standard:

Product specification levels (PSL 1, 2, 3, 3G and 4)

Performance requirement levels (PR1, PR2)

Design validation as per PR2F

Generally located at the wellhead, valves are designed for Oil&Gas processing, water and gas injection and gas lift. Velan’s DTP series are the optimal solution for controlling high levels of fluid pressure in the most difficult conditions such as dirty and corrosive fluid services.

Angle choke are traditional robust angle valves with a multistage trim and a corresponding plug specifically designed to provide high energy dissipation.

The valve's multi-stage technology and discrete tortuous path design divides the flow into many streams reducing pressure and fluid velocity avoiding cavitation, flashing or erosion phenomena.

Velan ABV offers the advantage of intechangeable plug and trim components, the valve has no welded internal parts, resulting low maintenance costs.

Actuation can be either hydraulic or pneumatic depending on the speed requested. Stepper actuators are an option for reaching the highest level of accuracy.

Material selection is fully customizable to meet customers project specifications.