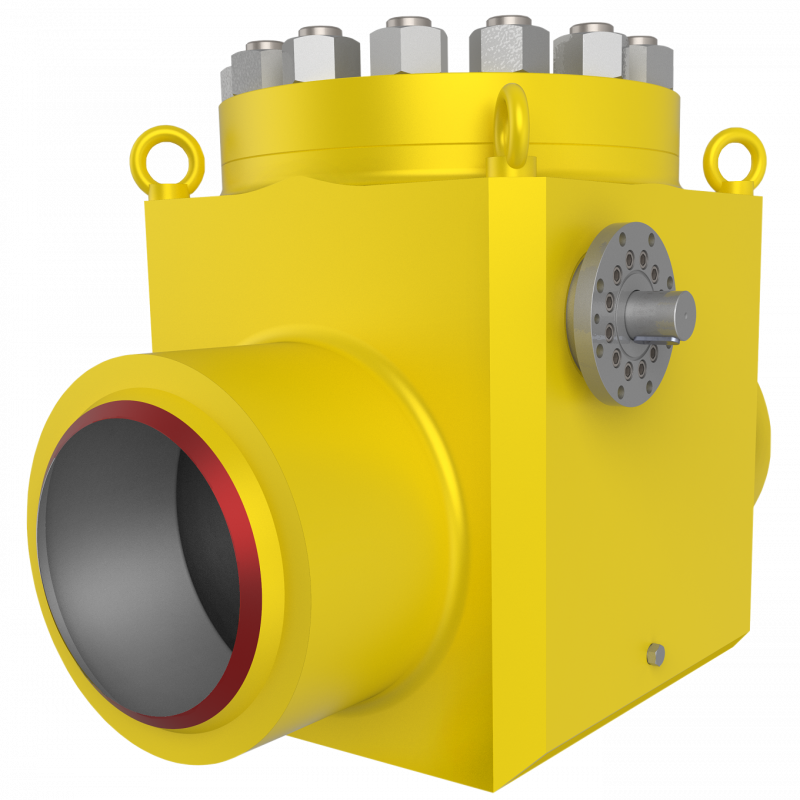

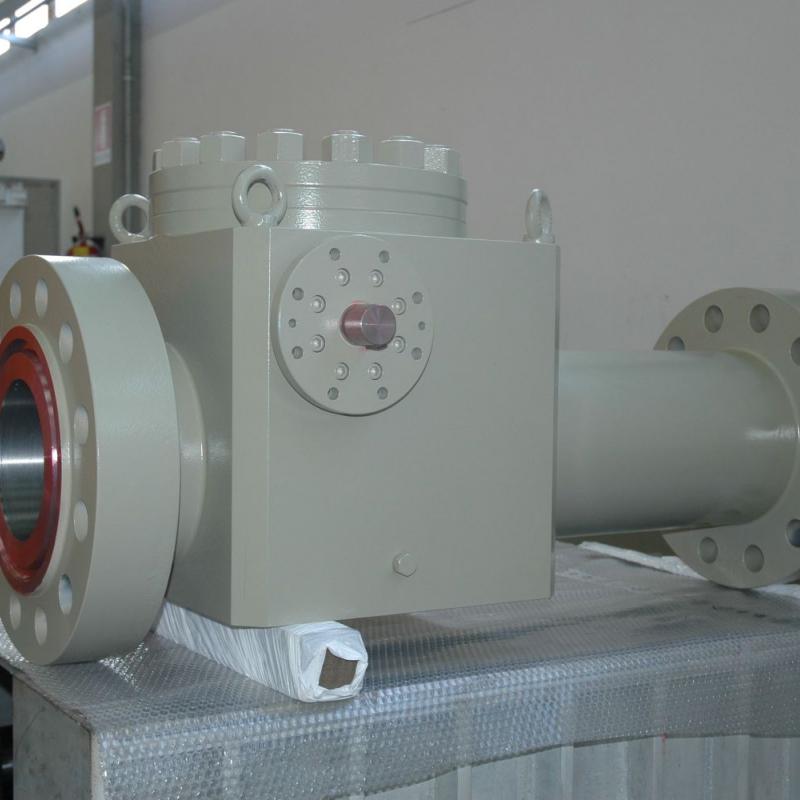

Subsea swing check valve

CSK

based on API 6DSS and customer requirements

NPS 2 - 36 (DN 50-900)

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

Hub connection

forged or cast one-piece

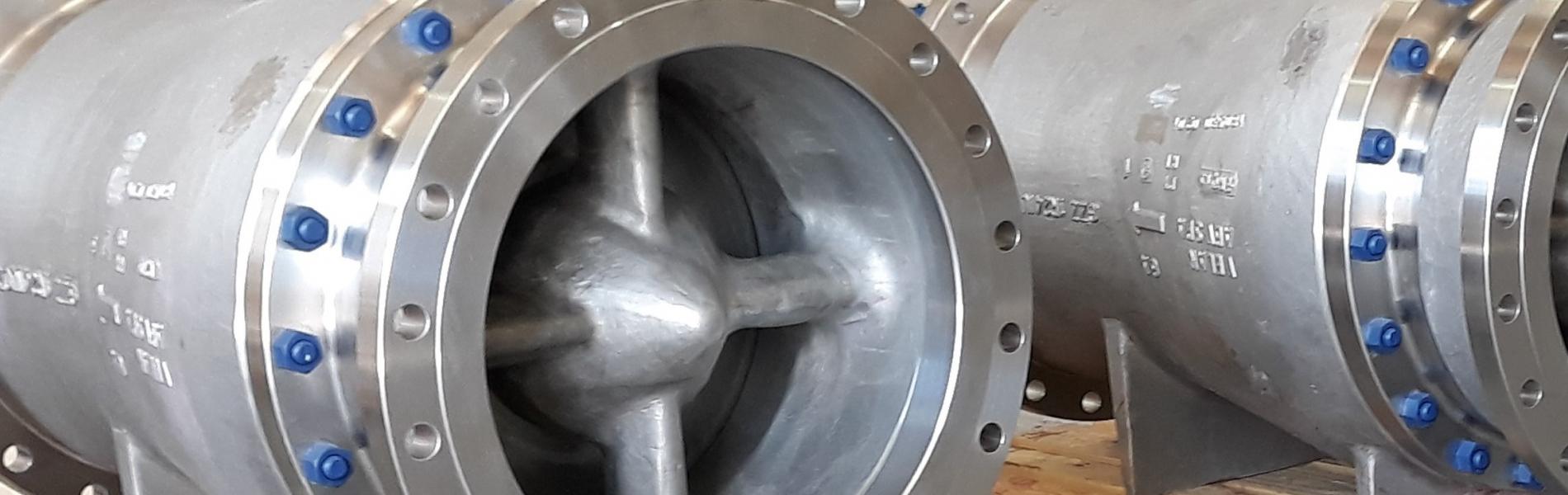

Metal-seated with hardfacing on disk and seat.

Welded-in-seat ring

Body/bonnet sealing with a secondary environmental soft seal as additional barrier to seawater ingress into the valve

Easy in-line maintenance as in the top-entry trunnion ball valve construction

Suitable for horizontal and vertical (flow-up) installation

Suited for low velocity service

Fully piggable design

De-clutchable device for lock opening during pipeline cleaning with ROV interface

Suitable for flow rates with corrosive and dirty fluids

Cathodic protection for the whole system, on request

automatic

Compliance with API 6DSS Inspection and testing

PED 2014/68/UE

Hyperbaric validation testing as per API 6DSS

Subsea swing check valves are suitable in water depths to 500 mt (1700 fit) and maintain an average service life of 25 years. Available in both forged or cast materials, the design ensures total reliability for high pressure and high temperature services.

The swinging action of the disc away from the seat allows forward flow and when the flow is stopped, the disc returns to the seat, preventing backflow. Swing check valves are suitable for installations in lines where pigging operations are required for various maintenance services. The piggable design makes the swing check valve ideal for installation in riser pipelines and subsea applications. Convenience of operation and simple in-line maintenance are essential features of our design. Internal parts can be inspected and repaired without removing the valve off the pipeline even where space is restricted as in the top-entry trunnion ball valve construction. The valve can be installed in both vertical and horizontal positions and offers unsurpassed quality and reliability– while the simple design minimizes maintenance costs.

Material selection is fully customizable to meet customers project specifications