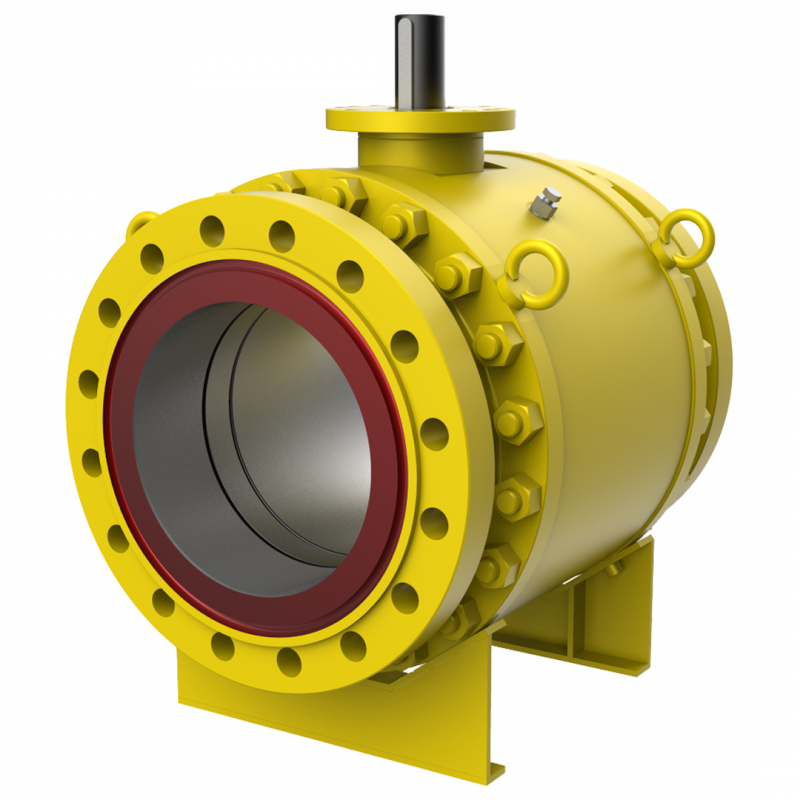

Subsea side-entry trunnion ball valve

API 6DSS Subsea side entry ball valve 2 piece

4 inch. ASME 2500, Ring joint connections, operated by ROV

Subsea PLEM valves, water depth 120 meters

API 6DSS Subsea side entry ball valve 3 piece

26 inch. ASME 1500, Ring joint connections, operated by ROV

Subsea PLEM valves, water depth 120 meters

SS2 and SS3

based on API 6DSS and customer requirements

NPS 2-48 (DN 50-1200)

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

Hub connection

Forged bolted two-piece and three-piece

Soft or metal seated with Hardfacing on ball and seats

Self relieving seats

Double piston seats

Combination seats

Double block and bleed design (DBB)

Anti-static device

Anti-blowout stem

O-ring/lip seal configuration

Body sealing designed in double O-ring configuration for sea water protection

CRA overlay on all dynamic sealing areas or on all wetted parts available

Manual: Gear with ROV receptacle or handwheel

Actuated: Hydraulic with or without ROV receptacle / handwheel override

baric compensator for operators

Compliance with API 6DSS Inspection and testing

SIL 3 Certification as per IEC61508

PED 2014/68/UE

Hyperbaric validation testing as per API 6DSS (available on request)

Cap test as per API 6DSS (available on request)

Subsea side-entry ball valves are suitable in water depths to 500 mt (1700 fit) and maintain an average service life of 25 years offering the utmost level of reliability and safety under high-pressure conditions even in harsh service with the presence of sand or solid particles.

Subsea side-entry ball valves may be completed with a subsea gear and ROV receptacle for remote operation by a ROV or with a handwheel for manual operation by diver. As an alternative, valves can be fitted with hydraulic subsea actuators, and fully compensated in a double or single acting configuration, with or without ROV override. Subsea side-entry ball valves are available in a wide range of materials and configurations to meet both customer’s requirements and the specific needs of an application