High pressure compact ball valve

API 6D High pressure compact ball valve

6x4 inch. ASME 1500, Grayloc compact flange connections, operated by Gear

In Offshore platform

API 6D High pressure compact ball valve

12 inch. ASME 2500, Compact flange connections, operated by Bare stem

For emergency shutdown in Offshore platform

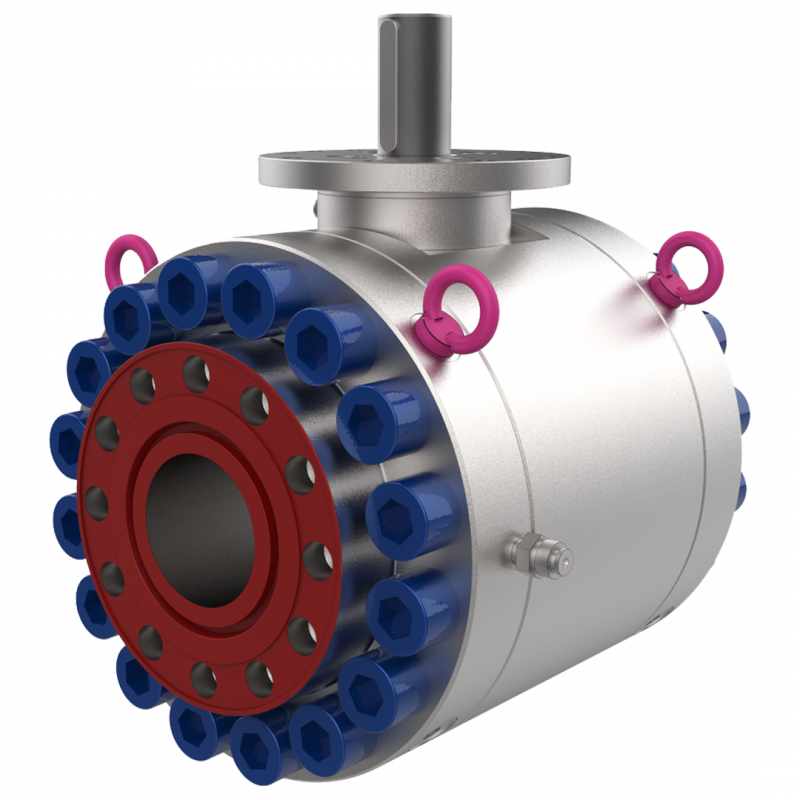

API 6D High pressure compact ball valve

20 inch. ASME 2500, Compact flange connections, operated by Gear

For Isolation process in FPSO topside

API 6A High pressure compact ball valve 2 piece

2 inch. API 10000, Compact flange connections, operated by Gear

For Isolation process in FPSO topside

API 6D High pressure compact ball valve

16X14 inch. ASME 2500, Compact flange connections, operated by Gear

For Isolation process in FPSO topside

API 6A Compact ball valve 2 piece

2.1/16 inch. API 15000, compact flange connections, operated by Gear

For Isolation process in FPSO topside

API 6A High pressure compact ball valve

16 inch. API 10000, Compact flange connections, operated by Gear

For Isolation process in FPSO topside

API 6 A High pressure compact ball valve

16 inch. API 10000, Compact flange connections, operated by Gear

For Isolation process in FPSO topside

BC2 and BC3

based on API 6D or API 6A or API 6DSS and customer requirements

NPS 2 -36 (DN 50-900)

NPS 1.13/16 –16.3/4 (DN 46-425)

Norsok L005 compact flange

Freudenberg/ Grayloc compact flange

Forged bolted two-piece and three-piece

Soft or metal seated with hard facing on ball and seats

Self relieving seats

Double piston seats

Combination seats

Double block and bleed design (DBB)

Secondary seals in pure Graphite

Anti-static device

Anti-blowout stem

Lip seal configuration

Emergency sealant injection on seats and stem available

Low fugitive emission stem packing available

CRA overlay on all dynamic sealing areas or on all wetted parts available

Compact and lightweight design

Lighter piping welding neck flanges with smaller dimensions offer 80% in weight savings

Manual: wrench or gear with padlocking

Actuated: Pneumatic/ Hydraulic/Electric

Compliance with API 6D & ISO 5208 & API 598 inspection and testing

Compliance with API 6A inspection and testing

Fire safe and fire tested as per API 6FA/607

SIL 3 Certification as per IEC61508

Fugitive Emission as per ISO15848

PED 2014/68/UE

Available as per API 6A standard:

Product specification levels PSL 1, 2, 3, 3G, and 4

Performance requirement levels PR1, PR2

Design validation as per PR2F

With several years of experience in high pressure ball valves for offshore platforms and FPSO, Velan ABV has developed a new generation of compact valves in both a single and double ball configuration. Our design provides a competitive solution in an ever-expanding market that faces technical and economic challenges. We offer a wide range of two or three-piece forged bolted body trunnion mounted ball valves. Two independent seats provide easy bidirectional sealing to ensure the greatest level of tightness and reliability under high pressure and temperature conditions in critical isolation services. High pressure compact ball valves have the same reliability and level of quality as traditional API valves but with significant space and weight savings due to the compact flange design integrated into the valve closures. Compact welding neck flanges that connect the pipeline to the valve provide further space savings. Design and selection of materials are fully customizable to meet the customer’s project specifications.